How to Use Sprues When Lasercutting with Paper

What is a “sprue”, and why should I use sprues with my lasercutting designs?

(This is another article in “Money-Saving Lasercutting Tips” – a free tutorial series that demonstrates effective and efficient lasercutting techniques. Tip #3 is all about those awful moments when you watch your precision-cut laser pieces drop down into the guts of the machine … and how to avoid those moments in future.)

Definition of a sprue

Sprues are most commonly seen in injection-moulded plastic toys. For a fuller description check out the Wikipedia definition, but briefly:

In the image below, there are little links that connect the plastic toy components to the frame. These are the sprues. They are created as part of the moulding process, but the useful secondary function of sprues is that they hold the components securely in position within the plastic frame, until you twist or cut the components out. So below, the pieces stay safely in place until the user needs them, rather than rattling around in a box or falling on the floor and getting lost.

Why do I need to use sprues when I’m cutting with a laser?

In laser cutting projects, you often need to cut light materials such as paper or card. But because the machines often blow and/or suck air during the cutting process, it’s very easy for a lovely piece of personalised wedding card to just fly away while you look on in horror.

It’s also really common to need to cut very small pieces from plastic or wood. But if they are smaller than the holes in the cutting bed of the laser machine, the pieces often fall through the holes as they have been cut. Then you either have to fish the pieces out of the cutting bed, or cut them again. This can potentially be a big waste of time and money.

This will happen to all lasercutter users at least once, but not everyone knows what to do to avoid it.

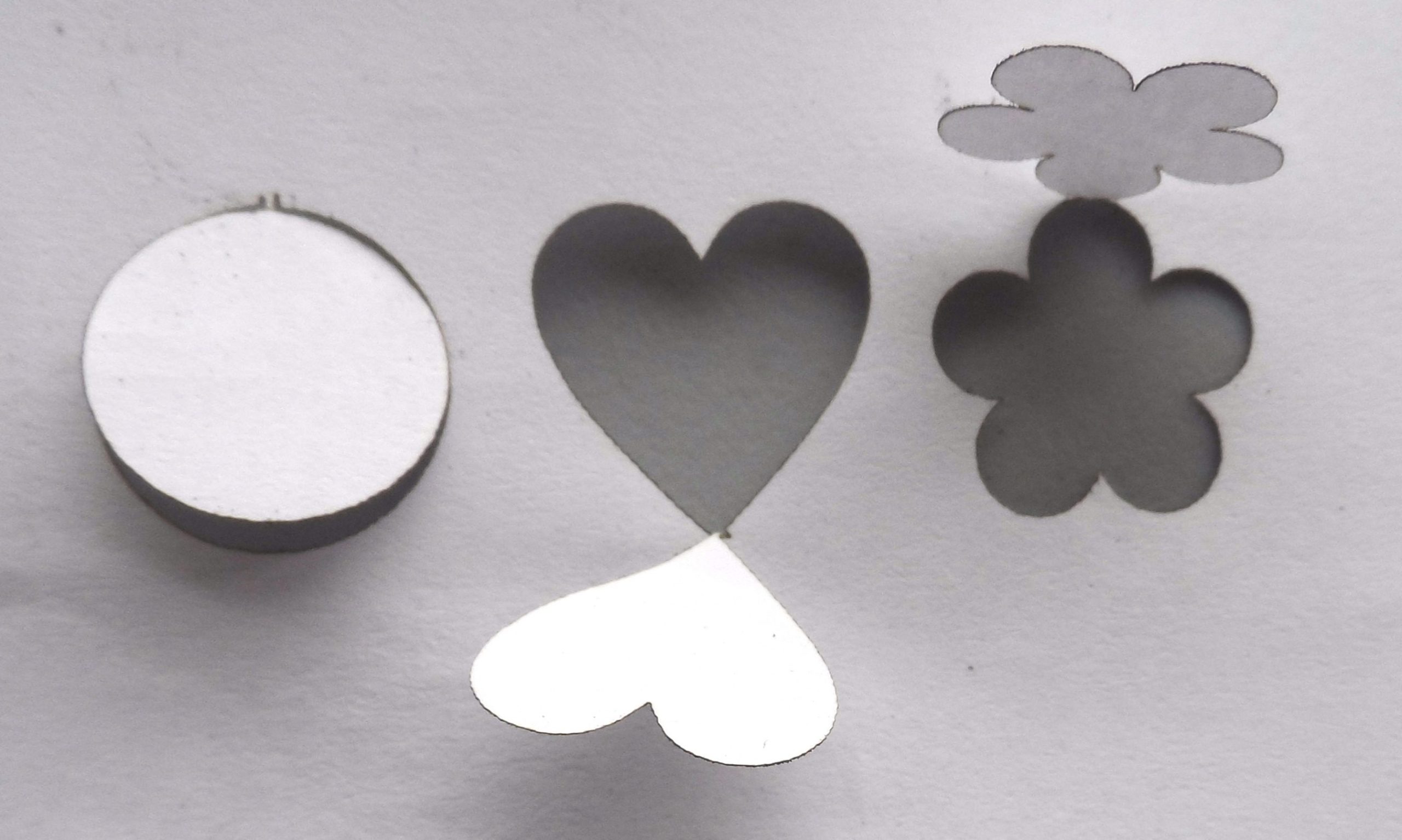

It might seem like it doesn’t matter very much because they are only tiny pieces and you can always cut more of them. But in the example image above I have lost 75% of my pieces. And what started out as a cutting job of only a few seconds, has now turned into either a search-and-rescue mission to retrieve the three little circles, or a waste of more time and material because I need to cut more pieces.

So we therefore need a way to cut the pieces that automatically stops them falling down or blowing away.

One solution is to use sprues, and to include them in the cutting design right from the start.

When to Use Sprues

Generally speaking, use sprues if the piece to be cut is less than 1cm squared, and anytime you are cutting a design from a piece of paper.

How to Design Sprues

You can create sprues very quickly and easily in most vector-based drawing software (e.g. Photoshop or CorelDraw). I happen to use CorelDraw, but the principles are the same for most other apps/programs.

For most lasercutting projects, a sprue is just going to be a small break in the cutting line. It should be:

- Big enough that the cut piece remains connected to the paper/wood/plastic

- Small enough that the cut piece can be pulled or pushed out of the sheet of paper/wood/plastic by hand

There are two main ways to create them. The first is to ‘manually’ make a tiny break in the cutting line, and the second is to use the Weld function to make the break.

Method 1: Make a ‘manual’ break in the cutting line

Step 1) Make sure that you can edit curves and manipulate/add nodes on the cutting path of the design. (In CorelDraw the “Shape Tool” lets you do this.)

Note: If you can’t see any nodes to edit, you may need to convert the shape to curves first (e.g. by right-clicking the mouse and selecting “Convert to Curves”):

2) Zoom in really close to the object (e.g. so that a 3mm line fills the whole screen), then add two new nodes as close to an existing node as you can manage:

3): Select the middle node of the group of three nodes, then break the path of the curve. (e.g. by right-clicking and choosing “Break Apart”):

4) That middle node should have broken in two, so take one of the two resulting nodes and drag it about half a millimetre outside the curve. Then do the same for the other new node. This creates a small break in the cutting line, so that when you cut the piece it should now remain fixed in place until you’re ready to push or tear it from the material you were cutting.

5) Use the laser cutter to cut out the shape.

The object can now be pushed or pulled out of the sheet of material that it was cut from.

(You may need a knife or scissors to help cut it free, and a file or blade to cut off any extra material left over.)

Conclusion

Using sprues helps laser cutters to save time, money, and annoyance. Instead of wailing in anguish as you watch another tiny precision-cut object fly away or disappear down a hole, consider using this little ‘design hack’ to avoid those problems.

Basically, whenever you’re lasercutting and you think “tiny” or “paper”, you should also think, “use sprues!”

I hope you found this article useful.

Method 2 (using the ‘Weld’ function to create sprues) is coming up later, but in the meantime if you have any comments or questions, please feel free to share them in the comments section or via the contact form.